Services

At Advanced Alloy Services Ltd we can offer a complete Revert Management solution.

Formula-Based Pricelist

We use publicly available published indices to create transparent formula based pricing for common alloys purchasing, which are updated on a monthly basis.

Revert Collections

We can supply stillages to best suit revert generated and arrange collection.

Testing and Grading

We use the latest XRF guns, Fuess testing and most importantly a wealth of industry knowledge and experience to accurately grade material. Where a full chemical assay is required we use carefully selected external fully accredited laboratories that have specific expertise in the material being tested.

Solids Processing

We have a full range of solids processing equipment including plasma cutting, alligator shears, guillotine, shot-blasting, cabinet blasting and balers.

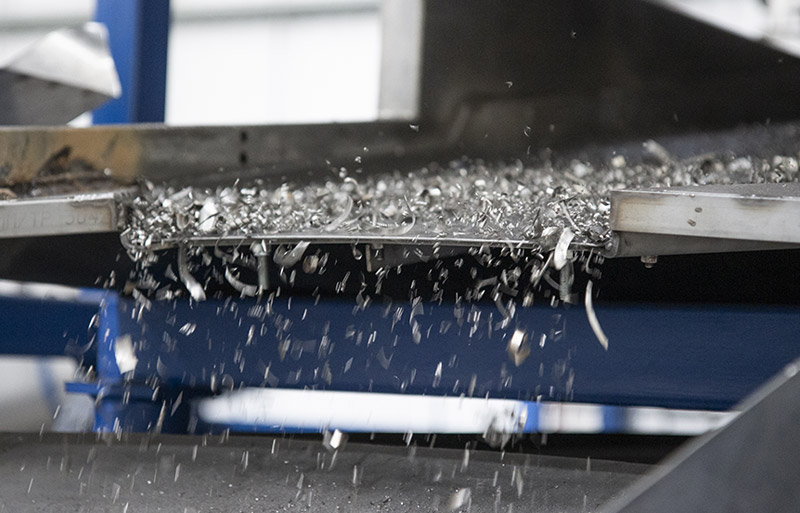

Turnings Processing

We have our own turnings processing facility where we inspect, crush, clean, rinse and dry nickel based turnings. We can provide a sample of turnings along with a button melted sample and full chemical analysis – ready for melting in a Vacuum Induction Furnace.

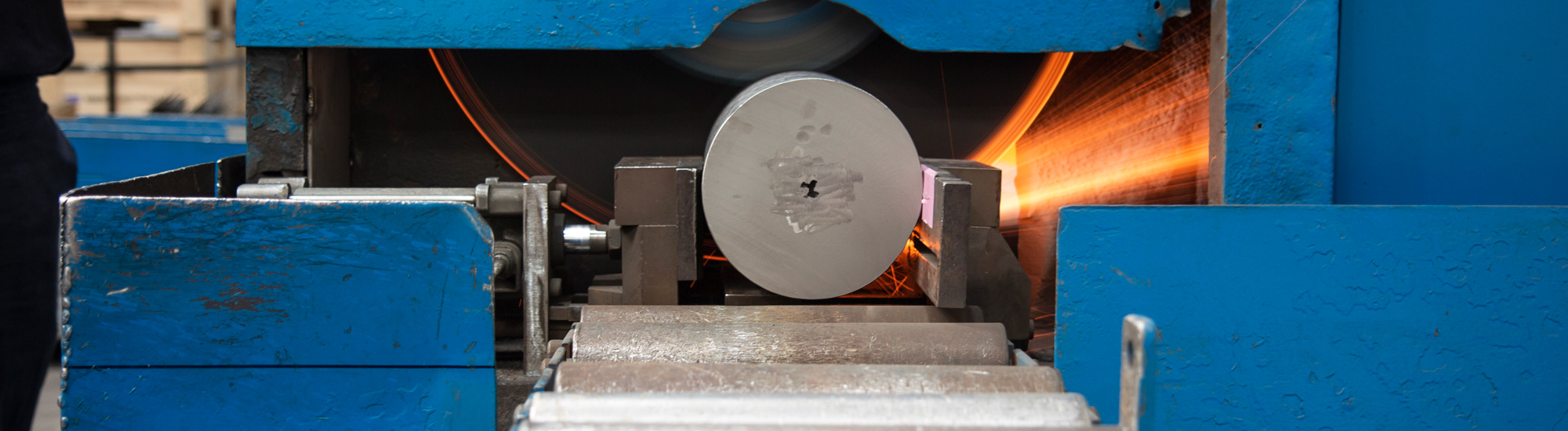

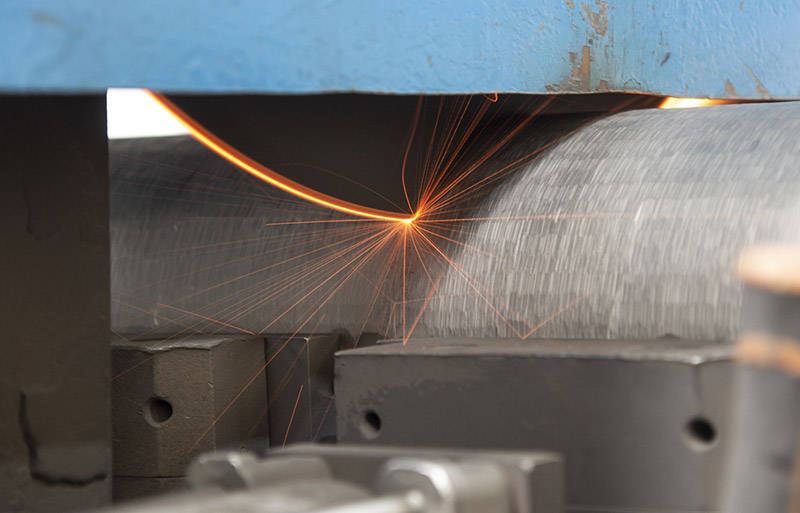

Cast stick bar-cutting

We store and hold customer owned bar-stock, which when required we cut accurately into specific weight billets to ensure there is just enough material for the casting process. Each billet is individually inspected and we now offer laser engraving of the billet which can be tailored to each customers’ requirements including material, cast identity, weight, QR / barcode, etc.

Storage

Our site holds Bonded Warehouse status and we have extensive racking allowing us to store material in a secure location ready for when it is needed.

Get in touch

We would love to talk to you whether you have pure metal, revert or toll-processing requirements. We would also be interested in reviewing and evaluating material that you would like to sell. We offer a friendly, expert service that you can trust and rely on.